Automobile Mazda lean burn technology

loss is also lower because one can open the throttle wider when adjusting air input. These two effects contribute to the higher fuel economy of lean-burn engines. shows these features. The tumble swirl control (TSC) valve and its effects are shown as The Z-lean engine uses a feature known as a TSX (tumble swirl multiplex) port to control the vortex inside the cylinder.

Combining this with an air mixture type injector which turns the fuel into a very fine spray and a high-energy ignition system ensures that it can operate on very lean mixtures up to. A special catalytic converter combines the NOx and HC into H2O, CO2, and N.

In-cylinder catalysts

A novel approach to reducing hydrocarbon emissions has been proposed and investigated by a team from Brunel University. The unburned hydrocarbons in spark ignition.

engines arise primarily from sources near the combustion chamber walls. A platinum-rhodium coating was deposited on the top and side surfaces of the piston crown and its effects were examined under a variety of operating conditions.

Electronic unit injection (EUI) – diesel fuel

The advantages of electronic unit injection are as follows. Lower emissions Through the use of higher injection pressures (up to 2000 bar), lower emissions of particulates and NOx are achieved, together with a reduction in the levels of noise traditionally associated with diesel engines.

`Further development potential

Draw mode on. Use arrow keys to move the cursor and press Spacebar to start a stroke. Release Spacebar to end the stroke.

In the EUI system, the fuel injection pump, the injector, and a solenoid valve are combined in one, single unit; these unit injectors are located in the cylinder head, above the combustion chamber. The EUI is driven by a rocker arm, which is in turn driven by the engine camshaft. This is the most efficient hydraulic and mechanical layout, giving the lowest parasitic losses. The fuel feed and spill pass through passages integrated in the cylinder head.

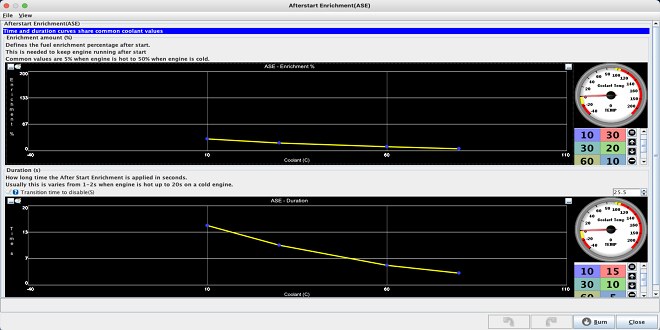

The EUI uses sensors and an electronic control unit (ECU) to achieve precise injection timing and fuel quantities. Sensors located on the engine pass information to the ECU on all the relevant engine functions.

This evaluates the information and compares it with optimum values stored in the ECU to decide on the exact injection timing and fuel quantity required to realize optimum performance. Signals are then sent to the unit injector’s solenoid-actuated spill valve system to deliver fuel at the timing required to achieve this performance.

The injection is actuated by switching the integrated solenoid valve. The closing point of the valve marks the beginning of fuel delivery, and the duration of closing determines the fuel quantity. The operating principle is as follows.

Electronically controlled pilot injection

A new feature was developed to meet tighter NO x emissions standards, without loss of fuel consumption. The pilot injection also reduces combustion noise.

Communication with another system

Linked to the ECU, the EUI system can communicate with other vehicle systems such as ABS, transmission, and steering, making further systems development possible.

Cylinder cut-out

This is used as a diagnostic aid and offers potential for fuel economy at idling and low loads.

Last word

The EU’s reliability is proven under field conditions. Experience in the truck market indicates a service life of at least 800 000 km.