Voltage correction Cranking enrichment

Pulse length is increased if the battery voltage falls, this is to compensate for the slower reaction time of the injectors.

The injectors are fired at every ignition pulse instead of every other pulse for cranking enrichment.

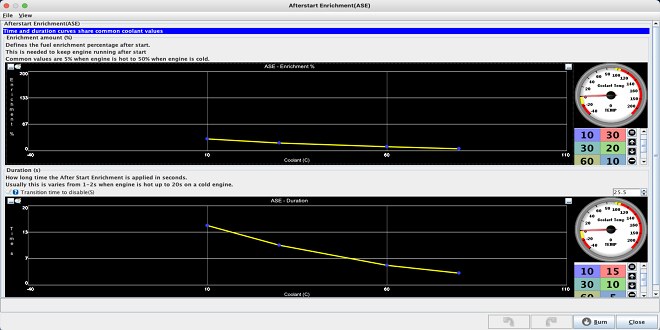

After-start enrichment

This is to ensure smooth running after starting. This is provided at all engine temperatures, and it decays over a set time. It is, however, kept up for a longer period at lower temperatures. The ECU increases the pulse length to achieve this enrichment.

Hot-start enrichment

A short period of extra enrichment, which decays gradually, is used to assist with hot starting.

Acceleration enrichment

Acceleration enrichment When the ECU detects a rising voltage from the throttle sensor the pulse length is increased to achieve a smoother response. The extra fuel is needed as the rapid throttle opening causes a sudden inrush of air and, without extra fuel, a weak mixture would cause a flat spot.

Deceleration weakening

The ECU detects this condition from a falling throttle potentiometer voltage. The pulse length is shortened to reduce fuel consumption and exhaust emissions.

Full load enrichment

This is again an increase in pulse length but by a fixed percentage of the look-up and correct value.

Overrun fuel cut-off

This is an economy and emissions measure. The injectors do not operate at all during this condition. This situation will only occur with a warm engine, throttle in the closed position, and the engine speed above a set level.

If the throttle is pressed or the engine falls below the threshold speed the fuel is reinstated gradually to ensure smooth take up.

Overspeed fuel cut-off

To prevent the engine from being damaged by excess speed, the ECU can switch off the injectors above a set speed. The injectors are reinstated once engine speed falls below the threshold figure. Hot-wire fuel injection is a very adaptable system and will remain current in various forms for some time. By way of summary, is a typical circuit diagram of the hot wire system.

Bosch Mono Jetronic – single-point injection

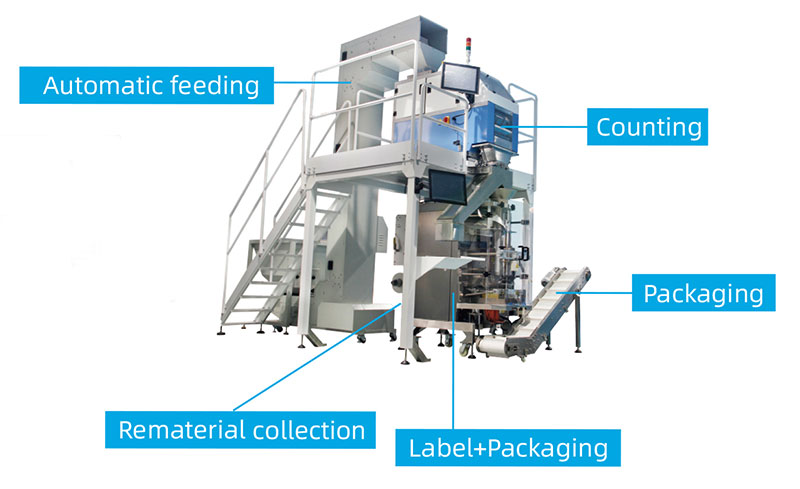

The Mono Jetronic is an electronically controlled system utilizing just one injector positioned above the throttle butterfly valve. The throttle body assembly is similar in appearance to a carburetor. A low-pressure (1 bar) fuel supply pump, as shown in, is used to supply the injector, which injects the fuel intermittently into the inlet manifold.

In common with most systems, sensors measuring engine variables supply the operating data. The ECU computes the ideal fuel requirements and outputs to the injector. The width of the injector pulses determines the quantity of fuel introduced. The injector for the system is a very fast-acting shown in the injector in section.

A pintle on the needle valve is used and a conical spray pattern is produced. This ensures excellent fuel atomization and hence a better ‘burn’ in the cylinder. In order to ensure accurate metering of small fuel quantities, the valve needle and armature have a very small mass. This permits opening and closing times of less than 1 ms.

Last word

The fuel supply to the injector is continuous, this prevents air locks and a constant supply of cool fuel. This also provides for good hot starting performance, which can be inhibited by evaporation if the fuel is hot.